How plastic foldable Returnable Packaging is reducing Carbon Emissions in the Automotive Supply Chain

Sustainability has become one of the defining challenges for the automotive industry. With global targets for reducing carbon emissions and the push for greener supply chains, every stage of production and logistics is under scrutiny.

Packaging and transport – often overlooked compared to vehicle design and fuel technology – represent a significant opportunity for change.

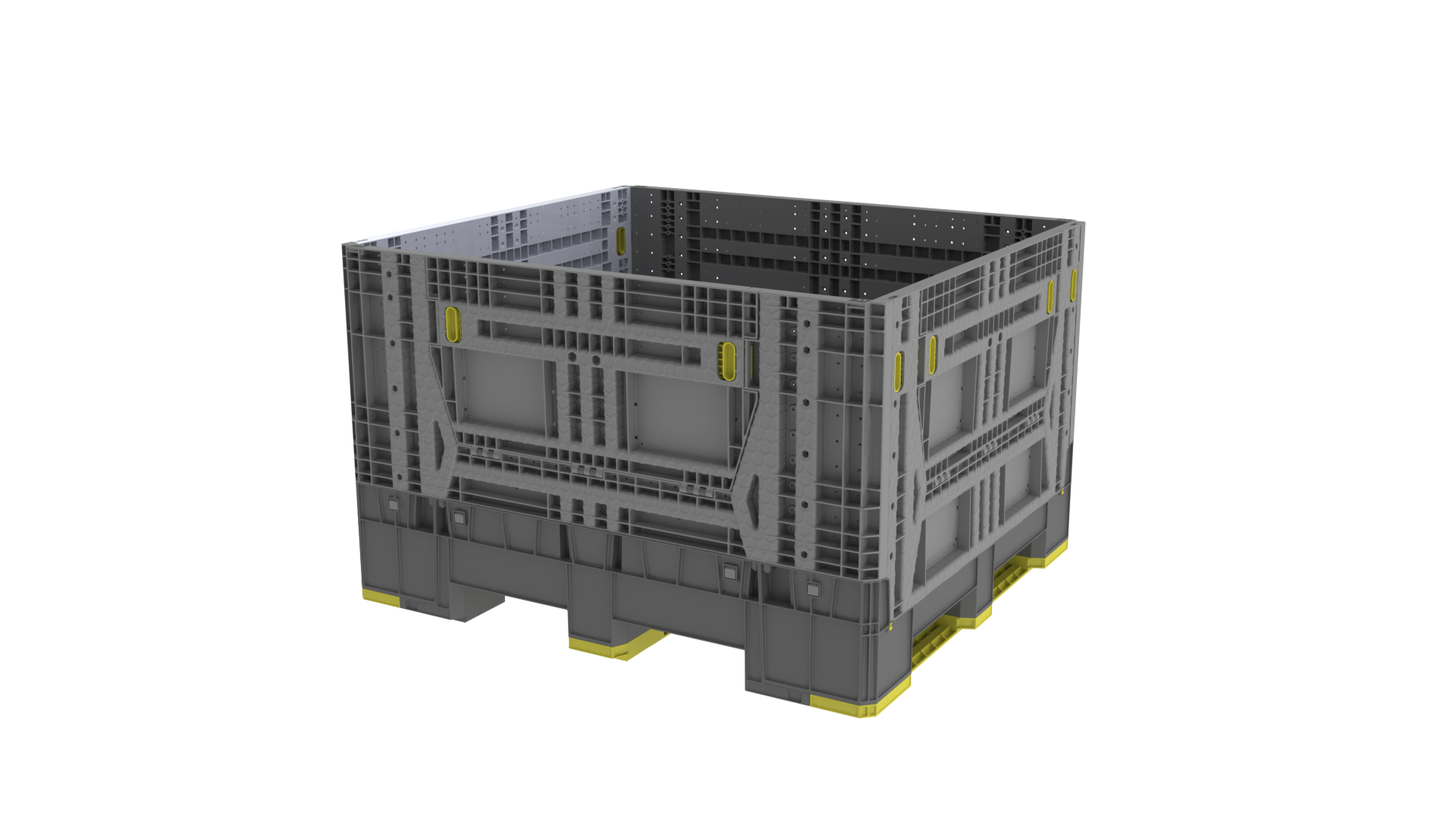

By adopting innovations such as Tri-Wall Circular’s YOYOBin Adjustable, automotive OEMs and Tier Suppliers can make measurable progress in reducing carbon emissions throughout both inbound and outbound supply chains.

Lightweight materials for greater efficiency

Traditionally, steel has been the material of choice for automotive packaging and containers. While durable, steel is heavy and contributes to higher fuel consumption when transporting goods.

The YOYOBin Adjustable, made from engineered plastic, provides a lightweight yet robust alternative to steel. By reducing the overall weight of containers, logistics providers consume less fuel across every journey. Scaled up across thousands of trips, this translates into significant emission savings and cost reductions, all while ensuring maximum protection for valuable components.

Through our collaboration with Global Logistics Emissions Council, we are able to introduce measurable cost savings for customers by reducing fuel consumption and emissions through the lightweighting of trucks.

Importantly, this gives us the ability to help customers calculate and prove these savings, making it easier to demonstrate the tangible impact of their supply chain choices to ISO 14085 standards.

These verified results can be directly included in ESG reporting, marking the first time packaging has been able to evidence its role in delivering real, quantifiable sustainability benefits.

Fewer journeys, lower emissions

The YOYOBin Adjustable is designed to optimised stacking whether full or empty, both during transportation and storage.

For inbound logistics, this means OEMs and suppliers can transport more parts per trip. For outbound journeys, empty bins can be collapsed and stacked efficiently, cutting down on wasted space and unnecessary trips.

This reduction in the number of vehicles on the road leads directly to lower fuel consumption and reduced carbon emissions, supporting net-zero targets across the automotive sector.

Closing the loop with recyclable materials

A key feature of Tri-Wall Circular’s YOYOBin Adjustable is that it is made from fully recyclable materials. Once a container reaches the end of its life, its plastic can be re-processed into new bins, avoiding waste and reducing reliance on virgin raw materials.

This closed-loop system not only lowers emissions linked to raw material production but also supports OEMs and Tier Suppliers in meeting strict ESG and sustainability commitments.

Extending lifespan through repair and maintenance

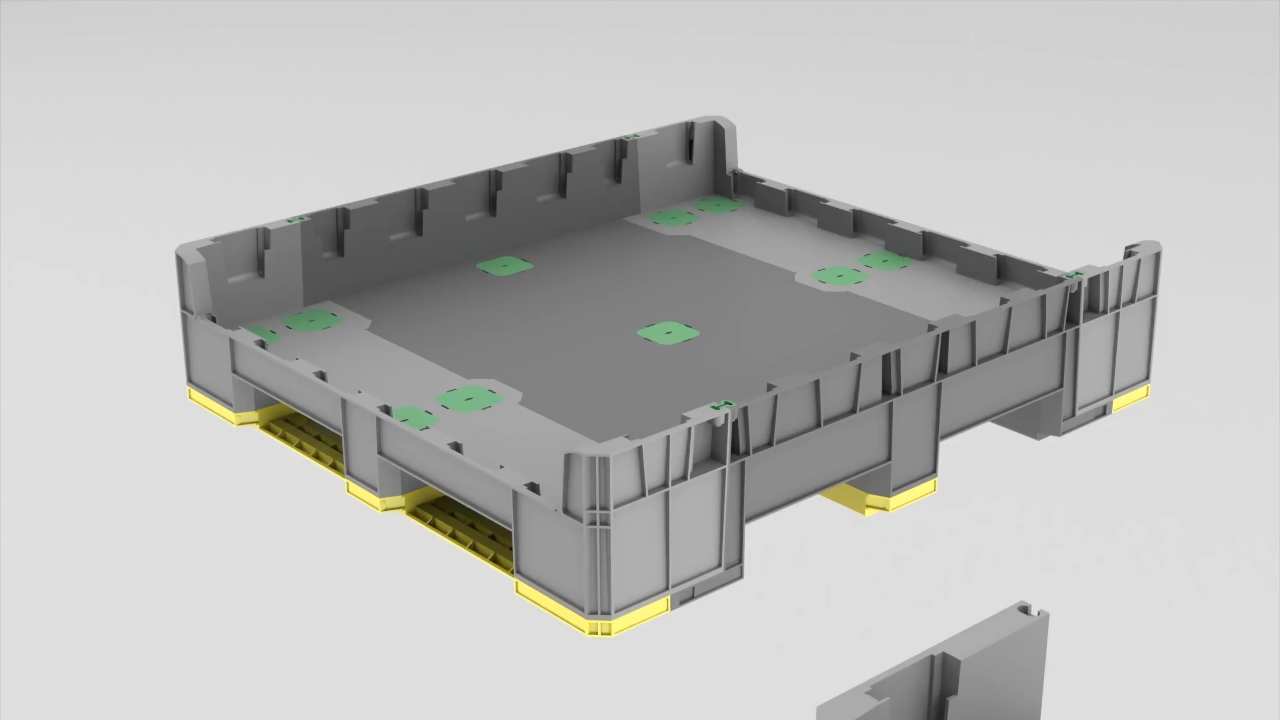

Replacing entire containers due to minor wear is costly and wasteful. The YOYOBin Adjustable is built with a modular design, allowing individual parts such as bases, sidewalls, or forkstraps to be replaced without discarding the whole unit.

This repair-and-reuse approach prolongs the container’s lifespan, reduces waste, and avoids the emissions associated with manufacturing new units. For automotive supply chains, this means a more sustainable and cost-effective long-term solution.

A Roadmap to a Greener Supply Chain

The automotive industry faces mounting pressure to reduce emissions across every link in the supply chain. By shifting to lightweight, recyclable, and repairable foldable plastic containers like the Tri-Wall Circular YOYOBin Adjustable, you can take meaningful steps toward sustainability.

From optimising transport efficiency to closing the materials loop, these innovations enable OEMs and Tier Suppliers to make tangible reductions in their carbon footprint.

Replacing steel with the YOYOBin Adjustable delivers the following savings –

- 3500kg – 4000kg saving per full load

- 7000kg – 9000kg saving on return journeys when empty.

- Save $13,000 in fuel for 1000kg removed from a truck over 200,000km

Why adjustable Returnable Packaging is a game-changer for Automotive OEMs and Tier Suppliers

In the fast-paced automotive industry, supply chains are under constant pressure to deliver greater efficiency, cost savings, and sustainability. Adjustable returnable packaging plays a pivotal role in this process – yet it is often overlooked as an area for innovation.

The Tri-Wall Circular YOYOBin Adjustable, a foldable and adjustable returnable packaging solution, is redefining the way OEMs and Tier Suppliers manage their logistics. Its unique design delivers a compelling return on investment, while also supporting wider operational and environmental goals.

One Container, Multiple Configurations: A Smarter ROI

Traditionally, automotive manufacturers have had to invest in multiple containers, stillages, or steel racks to accommodate different part sizes and configurations. This approach ties up capital and complicates inventory management.

Our 1350, 1500 and 1670 cube out the European mega trailer footprint, all with a 900kg capacity which is equal to a steel stillage. Therefore, the YOYOBin is a real game changer as it is a direct replacement for steel.

The YOYOBin Adjustable eliminates that challenge. By purchasing just one container with adjustable sides, you can adapt the bin to suit a variety of parts and components.

This modularity reduces the need for multiple packaging formats, maximising ROI and freeing up budget to be reinvested elsewhere in the supply chain.

A Cost-Effective Alternative to Steel

Steel containers have long been the industry standard for durability. However, they come with a high purchase price, heavier weight, and increased handling challenges.

The YOYOBin Adjustable provides a low-cost alternative to steel, without compromising on strength, resilience, or protection.

Manufactured from high-quality recyclable plastics, with a 900kg capacity it offers the durability required for rigorous automotive logistics while being lighter and more affordable to purchase and maintain.

Optimised Transport and Space Utilisation

Transport costs are a significant expense for OEMs and Tier Suppliers, and inefficient packaging only amplifies the problem.

The foldable design of the YOYOBin Adjustable allows for optimised stacking when both full and empty, ensuring more units can be transported per journey. This directly reduces the number of trips required, cutting fuel consumption and overall logistics costs.

For global supply chains where margins are under scrutiny, these efficiencies provide measurable long-term savings from the first trip to the last.

Protecting Parts and Reducing Damages

Quality is non-negotiable in automotive manufacturing. Damaged parts not only disrupt production schedules but also increase costs through replacements and delays.

The YOYOBin Adjustable can be fitted with customised dunnage systems to safeguard components. By minimising the risk of scratches, impacts, or contamination, it helps maintain part quality and reduces the hidden costs and time implications associated with product damage.

Driving Sustainability Goals

Sustainability is no longer optional – it is a key requirement for OEMs and their supply partners.

The YOYOBin Adjustable directly supports carbon reduction targets by lowering transport emissions through improved space efficiency and reduced journeys. Through our collaboration with Global Logistics Emission Council Framework, we are able to accurately calculate the sustainability savings using their methods which are ISO 14085 approved.

Additionally, being fully recyclable, the bins align with circular economy principles, ensuring materials are reused rather than sent to landfill. By replacing steel and single-use packaging, OEMs and Tier Suppliers can demonstrate tangible progress toward their environmental commitments.

Handling Efficiencies at Line Side

Beyond transportation, the YOYOBin Adjustable is designed for ease of use on the factory floor. Its fold-down sides improve accessibility for operators, reducing handling time and ergonomic risks.

This translates into greater efficiency at line side, where every second saved contributes to smoother workflows and improved productivity.

The Tri-Wall Circular YOYOBin Adjustable is more than just a packaging solution – it’s a strategic investment for OEMs and Tier Suppliers.

By combining modularity, cost-effectiveness, transport optimisation, part protection, sustainability, and handling efficiencies, it represents a true game-changer for the automotive supply chain.

Tri-Wall Circular Wins Automotive Leaders Sustainability Award for YOYOBin Adjustable

Tri-Wall Circular has been recognised for its commitment to innovation and sustainability after winning the prestigious Automotive Leaders Sustainability Award 2025 for its revolutionary YOYOBin Adjustable container.

The award, presented at the Automotive Leaders – Exploring the Automotive Transition event in London, celebrates outstanding contributions to advancing sustainability in the automotive supply chain. Tri-Wall Circular’s YOYOBin Adjustable stood out for its ability to deliver a genuinely circular solution that tackles the need for lighter, returnable, and space-saving packaging in a sector undergoing rapid transformation.

Developed in close collaboration with leading OEMs and Tier 1 suppliers, the YOYOBin Adjustable is a modular returnable packaging system that can be resized to accommodate different component dimensions, reducing the number of packaging solutions, cutting return logistics costs, and significantly reducing waste.

Sanjiv Takyar, Business Head at Tri-Wall Circular, commented:

“We are incredibly proud to receive the Automotive Leaders Sustainability Award for YOYOBin Adjustable. This innovation is the result of real collaboration with automotive manufacturers, working together to design a packaging solution that contributes to achieving circular economy goals. YOYOBin Adjustable delivers measurable benefits for sustainability and supply chain efficiency – it’s lightweight, returnable, and adaptable, helping to reduce emissions and waste across the logistics network.”

The award highlights Tri-Wall Circular’s role at the forefront of packaging innovation for the automotive sector and reinforces the company’s commitment to helping the industry achieve its environmental and operational objectives.

With electrification, complexity, and sustainability reshaping automotive logistics, the YOYOBin Adjustable is setting a new benchmark for future-ready packaging solutions.

Preserving Freshness with the YOYOBin Nestable: A Smarter Solution for Fresh Produce

In the fresh produce supply chain, ensuring the quality and freshness of fruit and vegetables is preserved is a top priority.

We have designed the YOYOBin Nestable specifically to help the fresh produce market improve product quality, reduce damage, and lower costs. Its unique design, featuring smooth contoured walls and a space-efficient nesting feature, provides unmatched protection for delicate fruits and vegetables while enhancing supply chain efficiency.

How Smooth Contoured Walls Reduce Damage

Fresh produce is highly susceptible to bruising, crushing, and other forms of damage during handling and transport. Traditional packaging, such as cardboard or wooden crates, often has sharp edges, seams, or rough surfaces that create pressure points, leading to spoilage.

The YOYOBin Nestable features smooth contoured walls that provide a seamless, soft surface for produce to rest against.

By distributing weight evenly and minimising impact points, the YOYOBin protects fruits and vegetables from cuts, abrasions, and deformation. Its smooth design also ensures produce slides easily during loading and unloading, reducing the risk of impact injuries.

This is especially critical for fragile items like berries, peaches, and tomatoes, where even minor damage can compromise quality.

Additionally, the YOYOBin’s innovative design ensures optimal stacking and stability during transportation, while built-in ventilation supports proper airflow. This helps regulate temperature and reduce ethylene gas buildup, further enhancing freshness and extending shelf life.

Benefits of the YOYOBin Nestable for Fresh Produce Markets

- Preserving Product Quality

The YOYOBin minimises damage and bruising, ensuring that fruits and vegetables retain their visual appeal and freshness. For growers, this means delivering produce that meets high customer expectations, improving overall satisfaction. - Cost Savings Through Waste Reduction

With the YOYOBin’s superior protection, businesses experience significantly lower waste rates. Less damaged produce translates to fewer financial losses and ensures a greater portion of the harvest reaches store shelves. - Enhanced Sustainability

As a returnable plastic container, the YOYOBin is built for reusability, significantly reducing waste associated with single-use materials like cardboard. Made from durable, recyclable materials, the YOYOBin supports circular economy goals while offering long-term cost efficiency. - Hygiene and Food Safety

The YOYOBin’s smooth, non-porous surface is easy to clean and sanitize, minimising contamination risks. This ensures compliance with food safety standards, building trust with consumers and meeting the rigorous demands of the fresh produce industry. - Strengthening Brand Reputation

Businesses using the YOYOBin can deliver consistently high-quality produce, enhancing their reputation for reliability and freshness. This fosters stronger relationships with retailers and customers alike.

The YOYOBin Nestable is more than just a container; it’s a strategic tool for the fresh produce industry. By addressing key challenges such as product damage, waste reduction, and operational inefficiency, it empowers growers, distributors, and retailers to improve their bottom line while delivering better produce to consumers.

From its innovative contoured design to its sustainable, reusable construction, the YOYOBin Nestable is setting a new standard in packaging. It not only protects produce but also streamlines supply chain processes, offering a practical solution that supports both profitability and sustainability.

Driving Down Supply Chain Costs: The YOYOBin Adjustable by Tri-Wall Circular

Our YOYOBin Adjustable, a lightweight, foldable returnable packaging solution is designed to unlock unprecedented cost-saving opportunities throughout the automotive and industrial supply chains.

By combining flexibility, durability, and sustainability, this innovative adjustable container is poised to transform supply chain costs for OEMs and Tier Suppliers.

The YOYOBin Adjustable was developed with the specific challenges of the automotive and industrial sectors in mind. Its adaptable design ensures compatibility with a wide range of components, from small parts to larger assemblies, making it the perfect solution for a dynamic and fast-paced industry.

One Bin, Three Sizes – Maximum Flexibility

The YOYOBin Adjustable is engineered to simplify packaging operations across the supply chain. Its unique adjustable design enables it to transition seamlessly between three sizes, making it a single solution for diverse product requirements.

This level of versatility significantly reduces the need for multiple container types, optimising costs while improving operational efficiency.

In addition to these larger sizes, the YOYOBin is available in the standard 1200mm x 1000mm footprint with multiple height and access configurations.

Cost-Down Opportunities Across the Supply Chain

Reduce inventory costs by consolidating packaging needs into one solution eliminates the expense and complexity of managing multiple packaging types, leading to leaner inventory and lower storage costs.

The YOYOBin’s foldable design minimizes the space required for empty container returns, reducing transport costs and carbon emissions. Its lightweight yet durable construction further enhances handling efficiency.

Manufactured using robust, high-quality plastic, the YOYOBin Adjustable ensures product protection, longevity of the container, and low maintenance compared to traditional packaging materials.

A Sustainable Advantage

In addition to its cost-saving features, the YOYOBin Adjustable champions sustainability:

- Lower Environmental Impact: Fewer container types mean reduced manufacturing demand, conserving resources and minimising waste.

- Reduced Carbon Footprint: The optimised footprint of all four sizes, when erect and folded, leads to fewer trips, cutting emissions and fuel costs while enhancing supply chain efficiency.

- End-of-Life Recyclability: Made with durable, 100% recyclable materials, the YOYOBin supports circular economy principles, helping businesses meet their sustainability goals.

The YOYOBin Adjustable is already gaining traction among leading OEMs and Tier Suppliers seeking innovative ways to reduce supply chain costs, enhance efficiency, and achieve sustainability targets.

YOYOBin Adjustable: A Sustainable Packaging Solution for the Automotive and Industrial Supply Chains

The YOYOBin Adjustable, the markets first adjustable, modular foldable container is designed to provide the Automotive and Industrial sectors with a lightweight, 100% recyclable packaging solution, optimised to reduce fuel consumption and carbon emissions.

Sustainability at the Forefront

YOYOBin Adjustable was developed with a deep commitment to minimising environmental impact while enhancing supply chain efficiency.

With the automotive and industrial sectors under increasing pressure to meet environmental legislation and their own sustainability targets, this innovative sustainable packaging solution provides a forward-thinking way to reduce waste, carbon emissions, and material usage.

Lightweight Design

The YOYOBin is designed to be lightweight without compromising durability, helping to reduce the fuel consumption of transport vehicles. Its reduced weight translates into fewer emissions during both delivery and return trips, significantly lowering the carbon footprint associated with shipping.

Foldable and Space-Efficient

Its foldable design enables the YOYOBin to be compactly stacked when empty, minimizing the space required for transportation and storage. This reduces the need for additional trips and helps optimise warehouse space, contributing to an overall more efficient and environmentally-friendly supply chain.

Adjustable to Multiple Sizes

The adjustable sizing feature allows one container to be used for various products, eliminating the need for multiple packaging formats. This versatility not only reduces packaging waste but also minimises the environmental burden of producing and transporting different container types around the globe.

Recyclable Plastic Material

Built from high-quality, recyclable plastic, the YOYOBin is designed to last, reducing the need for frequent replacements. At the end of its lifecycle, it can be fully recycled, supporting a circular economy and helping businesses meet their environmental goals.

A Solution for a Greener Future

The automotive and industrial industries are increasingly adopting sustainable packaging, and the YOYOBin Adjustable is perfectly aligned with these goals.

The YOYOBin Adjustable is already gaining traction among OEMs and Tier Suppliers in the automotive and industrial sectors, offering a sustainable alternative to traditional packaging methods. With its unique combination of lightweight design, adjustable sizing, foldability, and recyclability, it sets a new benchmark in packaging that reduces environmental impact while optimising efficiency.

Streamlining Automotive Logistics: How the YOYOBin Adjustable Cuts Costs with One Versatile Container

In today’s fast-paced and sustainability-focused world, the global automotive and industrial sectors are constantly seeking ways to streamline operations and reduce their environmental impact.

Traditionally, these sectors have relied on a range of returnable packaging solutions to accommodate different product sizes and requirements.

This often leads to:

- Increased inventory costs to manage multiple container types.

- Complicated logistics for tracking and storing various packaging formats.

- Higher environmental impact from the production of multiple container types.

- High fuel costs and wasted trips due to poor space utilisation.

An adjustable container that can adapt to three sizes solves these challenges by replacing multiple solutions with one versatile, reusable container – helping to streamline automotive logistics.

The Cost Benefits of a Single Adjustable Container

Reduced Inventory and Procurement Costs

Managing multiple packaging types often requires purchasing and storing large quantities of each type. By switching to a single adjustable container, OEMs and Tier Suppliers consolidate purchasing into one versatile product and reduce associated costs.

Lower Transportation Costs

Foldable containers take up less space when returned empty, meaning fewer trips are needed to transport them back for reuse. Adjustable sizes ensure that the container is always the right fit, eliminating the inefficiencies of shipping underutilised space in oversized and heavy packaging.

Minimized Replacement Expenses

Durable plastic containers last longer than expendable alternatives, reducing the need for frequent replacements. Steel Stillages are expensive to repair and can spend long periods of time out the supply chain, requiring replacements to be purchased or rented.

The modular design of the YOYOBin allows the user to replace only the damaged components and therefore, extending the life of the container whilst minimising repair and maintenance costs.

What are the environmental benefits of choosing the YOYOBin Adjustable?

Reduced Manufacturing Impact

Every additional type of returnable packaging manufactured leaves an environmental footprint, from raw material to energy consumption during production. By opting for a single, multipurpose solution you can significantly reduce the demand for multiple containers, cutting down on the carbon emissions associated.

Lower Carbon Emissions in Transport

The foldable design reduces the number of trucks required for return trips, directly lowering fuel consumption and emissions as well as reducing maintaining vehicle fleets. These are costs that are passed on to the OEM and ultimately, end of up on the bottom line.

Waste Reduction

YOYOBin Adjustable plastic containers are built to last, reducing waste compared to single-use packaging or less durable materials. At the end of their lifecycle, YOYOBin Adjustable is 100% recyclable with the regrind being used in the future production of containers, contributing to a circular economy.

Switching to a single, foldable, and adjustable returnable packaging solution is a win-win for streamlining automotive logistics and the planet. The cost benefits are clear: lower inventory expenses, fewer replacements, and optimised logistics. But the environmental benefits are even more compelling.

By reducing the manufacturing demand for multiple packaging solutions and streamlining the supply chain, OEMs and Tier Suppliers can make a significant contribution to reducing their carbon footprint.

How does YOYOBin Nestable optimise space in the Fresh Produce Supply Chain?

Incorporating the YOYOBin Nestable into the fresh produce supply chain optimises both storage and transportation, allowing you to improve efficiency, reduce costs and reduce the environmental impact of your packaging.

Efficient space utilisation is critical in the fresh produce supply chain, where high-volume yields demand streamlined storage and transport solutions. The YOYOBin Nestable is designed to address these needs, offering farmers, distributors, and wholesalers a returnable packaging solution to optimise logistics and reduce costs without compromising on quality.

Optimised Container Footprint

One standout feature of the YOYOBin Nestable is its optimised footprint. The containers are designed to maximize trailer and container space, ensuring no wasted areas during transport. The careful footprint sizing allows bins to fit seamlessly into standard trailers, enabling agricultural businesses to transport more produce in fewer trips. This design not only reduces transportation costs but also cuts down on emissions, supporting growers’ efforts to lower their environmental footprint.

Unrivalled Nesting Capability

The YOYOBin Nestable’s stacking and nesting capabilities further enhance its space efficiency. When empty, the bins nest tightly within each other, significantly reducing the space required which enables compact storage and return transport. This feature is particularly valuable for seasonal growers, allowing warehouses, cold storage, and transport vehicles to be efficiently managed during off-peak periods. For full storage, the stackable design enables secure vertical stacking, maximizing storage capacity without jeopardising the safety or quality of fresh produce.

Produce Protection and Quality

Constructed from high-quality, recyclable materials, YOYOBin Nestable containers are durable enough to withstand demanding agricultural environments in the fresh produce supply chain, from fields to cold storage. The containers’ design ensures they protect produce effectively, minimizing damage and reducing waste. With their easy-to-clean surfaces, YOYOBin Nestable meet the strict hygiene standards required in food distribution, making them a sustainable and cost-effective choice for growers, distributors and processors.

Unlocking Fill Optimisation with the YOYOBin Adjustable in the Automotive Supply Chain

In the automotive supply chain, efficient space utilisation, or fill optimisation is essential for reducing costs and carbon emissions. The YOYOBin Adjustable offers a breakthrough solution, designed to maximise space and streamline packaging and supply chain operations for OEMs and Tier Suppliers.

Optimise Space in Automotive Supply Chain

The YOYOBin Adjustable is a modular, foldable plastic container specifically designed to optimise the footprint of both European mega trailers and ISO Sea Containers. Whether containers are full or folded, their dimensions ensure that the available floor space and stacking height are fully used. This cubing out of transportation ensures that automotive suppliers can maximise the number of parts shipped in each journey.

This optimisation means no wasted space whether using the smallest or largest size of the YOYOBin. For automotive OEMs and Tier Suppliers, this translates into fewer trips to move the same volume of parts, significantly reducing transportation costs.

Market-Leading Space Efficiency When Empty

Traditional containers, such as rigid plastic bins or metal stillages, occupy the same space when empty as when full. This inefficient use of space results in increased costs for return trips, as only the same number of empty containers can be shipped at any one time.

The YOYOBin Adjustable provides a market-leading advantage in this regard, thanks to its foldable design. Once emptied, the container collapses to a fraction of its full size, enabling significantly more units to be shipped on return journeys. This innovative approach to space efficiency means more containers can be returned per trip, reducing both fuel consumption and transportation costs.

The range of YOYOBin Adjustable containers are available in 3 interchangeable sizes –

More Parts per Trip

Another critical component of fill optimisation is the ability to transport more product by maximising the payload. Unlike heavier, rigid containers, the lightweight construction of the YOYOBin Adjustable increases the overall cargo capacity per trip. This means that more parts or products can be shipped, reducing the total number of trips required and lowering overall shipping, fuel, and labour costs.

For automotive suppliers, the benefit is clear: the YOYOBin Adjustable enables businesses to ship more parts per journey, improving productivity while driving down logistical costs.

Sustainable and Cost-Effective

The combination of optimised space use, reduced return trips, and increased payload capacity means that the YOYOBin Adjustable helps businesses reduce their carbon footprint. By enabling fewer shipments overall, the container cuts down on fuel consumption and associated emissions, aligning with industry efforts to lower environmental impact.

In addition, fewer trips and increased load capacity result in reduced operational costs, making the YOYOBin Adjustable both a cost-efficient and environmentally responsible solution.

The YOYOBin Adjustable offers automotive OEMs and Tier Suppliers a unique solution that maximises fill optimisation at every stage of the supply chain. With its foldable, modular design, it optimises space, improves load capacity, reduces costs, and lowers environmental impact.

YOYOBin Adjustable’s Modular Packaging Revolutionises Automotive Supply Chain

Efficiency is paramount in the automotive supply chain and modular returnable packaging is fundamental solution to achieving efficiency at every key stage of a global supply chain, transforming the efficiency, costs and sustainability of the global supply chain.

Every component, every process, every decision affects the bottom line and the overall productivity of the industry. In this complex ecosystem, the role of returnable plastic containers cannot be overstated enough.

But what if these container solutions could be optimised even further?

Enter modular design – a game-changer that promises to revolutionise the efficiency and sustainability of the automotive supply chain. Tri-Wall Circular’s YOYOBin Adjustable range is designed with adjustable size options, providing OEMs and Tier Suppliers with a single modular returnable packaging solution to ship component parts.

Modular Returnable Packaging

At its core, modular design entails creating systems or products with interchangeable components that can be easily assembled or disassembled. When applied to returnable plastic containers, this approach unlocks a myriad of benefits for the automotive industry.

First and foremost, modular FLCs offer unparalleled flexibility. Traditional containers are often single-purpose, designed to transport specific parts or components. In contrast, modular containers can be customised and reconfigured to accommodate various components, thereby streamlining logistics and reducing the need for multiple container types.

A Sustainable Packaging Solution

Modular FLCs such as the YOYOBin Adjustable help to deliver sustainability benefits throughout each stage of the global automotive supply chain.

The YOYOBin Adjustable enables OEMs and Tier Suppliers to remove waste from their supply chain operations, by eliminating the need for single-use materials such as plastic and cardboard.

With the ability to reconfigure the YOYOBin Adjustable, you no longer require multiple packaging solutions. The footprints of the YOYObin Adjustable have been selected to maximise load-fill efficiency on all standard transportation methods. This reduces the carbon emissions of transportation and energy consumption to manufacture and ship alternative packaging.

The modular design allows for easy repair and maintenance, further prolonging the lifespan and removes the need to replace the container.

Adjusting Packaging to Market Requirements

The adaptability of modular FLCs enhances supply chain resilience. In an industry plagued by uncertainties, such as fluctuating demand and supply chain disruptions, the ability to quickly reconfigure the YOYOBin Adjustable containers can mitigate risks and ensure continuity of operations. Whether accommodating sudden changes in production volumes or adapting to evolving transportation requirements, modular containers provide the agility needed to navigate volatile market conditions.

Additionally, the YOYOBin has been designed to drive cost savings across the supply chain. Their reusability and durability translate into lower packaging expenses and reduced transportation costs. By optimising space utilisation and minimising empty container returns, they maximise operational efficiency and improve overall profitability for automotive manufacturers and suppliers alike.

From enhanced flexibility and sustainability to improved resilience and cost savings, modular YOYOBin Adjustable containers represent a paradigm shift in logistics optimisation. As the automotive industry continues to evolve, embracing modular design is not just a choice but a necessity for staying competitive in an ever-changing landscape.