YOYOBin Nestable’s Interstacking Design Revolutionises Global Fresh Produce Supply Chain Efficiency

The global fresh produce supply chain is a complex and demanding network that requires efficient, cost-effective, and sustainable solutions for packaging and transportation. The YOYOBin Nestable’s interstacking features offer significant benefits, particularly in terms of maximising space, reducing costs, and minimising environmental impact. These benefits are evident both when the containers are full and during their return journey when empty.

Efficient Space Utilisation

One of the primary advantages of the interstackability of the YOYOBin Nestable is the efficient use of space. When filled with fresh produce, the containers can be securely stacked, maximising the use of vertical space during shipping and when in storage. The interstacking feature ensures that the containers remain stable during transit, reducing the risk of damage to fresh produce which can be easily bruised or spoiled if mishandled.

Cost Reduction

The efficient stacking of full containers directly translates to cost savings. By optimising the use of space in shipping and storage, you can transport larger quantities of products in a single trip. This reduces the number of trips needed, cutting down on fuel consumption and associated transportation costs. The durability of the YOYOBin Nestable means they have a longer lifespan compared to single-use alternatives, leading to lower long-term packaging costs.

Sustainability and Environmental Impact

Incorporating interstacking design features also aligns with the sustainability goals of fresh produce growers, reducing the reliance on cardboard, wood and single-use plastic. By reducing the amount of waste generated during each harvest and shipment, growers can significantly reduce their environmental footprint and work towards acheiving their sustainability goals. Additionally, the YOYOBin Nestable containers typically includes features that make them easy to clean and sanitise, ensuring that they can be safely reused many times over during their lifespan.

Benefits During the Return Journey

The advantages of interstacking design are not limited to when the containers are full. On the return journey, when the containers are empty, interstacking is equally beneficial. Empty YOYObin Nestable containers can be nested, which dramatically reduces the space they occupy. This space-saving capability means that more empty containers can be transported back in a single trip, reducing the number of return trips required. This not only lowers transportation costs but also minimises carbon emissions associated with empty hauls.

Enhanced Logistics and Handling

Interstacking contributes to smoother logistics and handling processes. Their uniform shape and stackability make them easier to handle with standard equipment, such as forklifts and pallet trucks. This uniformity reduces the time and labour required to load and unload containers, improving overall operational efficiency. Additionally, the robustness of reusable plastic containers ensures that they can withstand the rigors of repeated handling without compromising their structural integrity.

By enabling secure stacking when full and efficient nesting when empty, the YOYOBin Nestable provides a versatile and environmentally friendly packaging solution. As the demand for fresh produce continues to grow, the adoption of such innovative packaging solutions will be essential in meeting the needs of a modern, efficient, and sustainable supply chain.

Lightweighting Returnable Packaging in the Automotive Industry

In the automotive supply chain, efficiency, sustainability and lightweighting are not just buzzwords; they are crucial components for success. One area where these principles intersect is in the packaging used for transporting parts.

Traditionally, heavy metal containers have been the go-to solution for returnable packaging, with plastic FLCs becoming a common alternative in recent years.

However, the industry is witnessing a paradigm shift towards lightweight, foldable alternatives, such as the new innovative YOYOBin Adjustable, delivering even further weight-reduction benefits over its metal and plastic competitors.

What is Lightweighting in Packaging?

Lightweighting refers to the process of designing products to reduce their weight without compromising their strength, durability, or functionality. In the context of returnable packaging, it involves replacing heavy materials like steel with lighter alternatives, such as high-density plastics or composites. This transformation not only lowers the weight of the containers themselves but also enhances overall efficiency in handling and logistics.

Our cutting-edge design techniques have resulted in a class-leading capacity of 900kg YOYOBin Adjustable whilst maintaining a light tare weight.

The YOYOBin Adjustable

The YOYOBin Adjustable is a prime example of how innovative design can transform packaging solutions. This foldable container is designed to be highly adaptable, allowing it to adjust depending on the different sizes and shapes of parts. It is made from durable, lightweight polypropylene, offering a significant reduction in weight compared to traditional metal containers.

The design allows the containers to be folded when not in use, greatly reducing space required when transported empty and when in storage.

Benefits of Lightweighting with the YOYOBin Adjustable

1. Reduced Transportation Costs

An immediate benefit of lightweight packaging is the reduction in transportation costs. With tare weights ranging from 36.5kg to 53kg, the YOYOBin Adjustable removes a significant amount of weight per truck meaning lower fuel consumption, reducing carbon emissions and fuel costs.

2. Contribute to Sustainability Goals

Automotive OEMs and Tier Suppliers are under increasing pressure to adopt sustainable practices. Lightweight plastic packaging containers have a lower carbon footprint than metal containers, throughout their entire lifecycle from production, in use and when recycled. Moreover, YOYOBin Adjustable is 100% recyclable, aligning with circular economy principles and reducing waste.

3. Space Efficiency:

One of the standout features of foldable packaging is its ability to save space when stacked on a trailer. All size variations of YOYOBin Adjustable are designed to optimise the fill capacity of a trailer when erect and folded. This eliminates wasted space and unnecessary weight, allowing you to ship more per journey.

4. Cost-Effective and Flexible:

The initial investment in lightweight returnable packaging may sometimes be higher. The YOYOBin Adjustable range is available at a significantly reduced price in comparison to metal stillages. Therefore, the containers are commercially viable from their first use. Not to mention, the modular design of the YOYOBin Adjustable provides unrivalled flexibility for you to ship a variety of parts efficiently by purchasing only the components you require to adjust the size of the bin. There is no need to purchase multiple packaging solutions.

The transition from heavy metal to lightweight, foldable packaging represents a significant step forward for the automotive industry. YOYOBin Adjustable epitomises the benefits of this shift, offering cost savings, improved safety, sustainability, and efficiency. As the industry continues to innovate and prioritise sustainable practices, lightweighting returnable packaging will undoubtedly play a crucial role in shaping the future of automotive logistics.

YOYOBin Nestable Containers: Remove Single Use Packaging from the Fresh Produce Supply Chain

In the agricultural sector, efficiency and sustainability are critical to both economic success and environmental stewardship. As the world becomes increasingly conscious of the need to reduce waste and carbon footprints, the industry is under pressure to find innovative solutions that balance productivity with environmental responsibility.

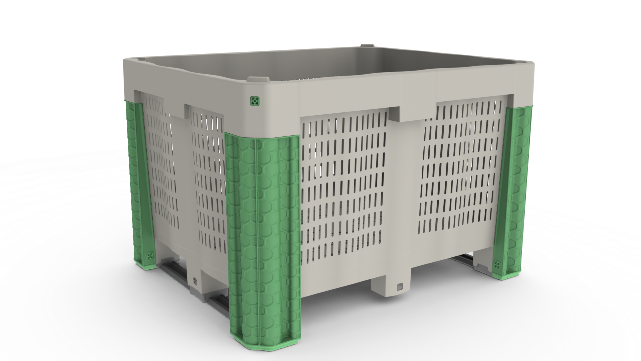

The new YOYOBin Nestable has been specifically developed with sustainability at the forefront of it’s design.

The versatile plastic container designed with the option of solid or vented sides, is a superior alternative to traditional single-use, expendable packaging such as cardboard at each stage of the supply chain.

Reducing Costs Through Reusable Packaging

One of the primary benefits of the YOYOBin Nestable containers is their potential to significantly reduce costs for agricultural businesses. Unlike single use materials, which deteriorate quickly and must be replaced frequently, our durable plastic containers are designed for long-term repeated use. Reusability leads to a substantial reduction in the recurring costs associated with purchasing and disposing of single-use packaging materials.

Moreover, the design of YOYOBin Nestable containers allows for efficient nesting when empty, minimising storage space and reducing transportation costs. These containers are robust enough to protect agricultural products during transit, reducing the likelihood of damage and the associated costs of product loss or spoilage. Over time, the initial investment in these containers will lead to significant savings, enhancing the bottom line for farmers and distributors.

Minimising Waste and Environmental Impact

The environmental benefits of using YOYOBin Nestable containers are profound. The agriculture industry generates a significant amount of waste, much of it from packaging. Cardboard, while recyclable, often ends up in landfills due to contamination or insufficient recycling infrastructure. In contrast, the YOYOBin Nestable containers are designed for longevity and can be reused numerous times, dramatically reducing the amount of waste produced.

Furthermore, the durability and reusability of these plastic containers mean fewer resources are consumed in the manufacturing of packaging materials. This reduction in resource use contributes to a lower overall environmental footprint. By adopting a circular economy approach—where products are reused rather than discarded—the agriculture industry can play a crucial role in reducing pollution and conserving natural resources.

At the end of their lifecycle, the YOYOBin Nestable is 100% recyclable with the ability for the recycled materials to be reused by customers when re-ordering new containers. This further reduces the environmental impact by reducing the quantity of virgin materials needed.

Enhanced Sustainability and Brand Image

Consumers today are increasingly aware of the environmental impact of their purchases and are more likely to support brands that demonstrate a commitment to sustainability. By using YOYOBin Nestable containers, agricultural producers and distributors can enhance their sustainability credentials. This shift not only reduces their environmental impact but also serves as a powerful marketing tool, appealing to eco-conscious consumers and potentially commanding a premium for their products.

The transition from single-use, expendable packaging to durable, reusable solutions like the YOYOBin Nestable is more than a practical choice; it is an essential step towards a more sustainable and cost-effective agricultural industry. By embracing these innovative containers, businesses will reduce operational costs, minimise waste, and significantly lower their environmental impact. In doing so, they not only safeguard their profitability but also contribute to a more sustainable future for all. The adoption of such practices is not just beneficial; it is necessary for the longevity of the agricultural sector and the health of our planet.

Maximising Freshness and Efficiency of the Fresh Produce Supply Chain with YOYOBin Nestable

The evolution of the fresh produce supply chain towards sustainability has found a powerful ally in the YOYOBin Nestable, a fully nestable returnable plastic container. Beyond the environmental benefits, YOYOBin Nestable plays a crucial role in preserving the freshness and quality of fruits and vegetables while simultaneously streamlining operations and reducing labour costs.

Preserving the freshness of perishable goods is paramount in the fresh produce industry, and plastic returnable bins excel in this aspect. The durable construction of these containers shields delicate fruits and vegetables from physical damage during transportation, ensuring that they reach their destination in optimal condition. The enhanced protection minimises the risk of spoilage, contributing to a reduction in food waste and ultimately providing consumers with higher quality produce.

By adopting a system where produce remains in the same container from harvesting to retail display, businesses can achieve significant savings on labor costs associated with handling and repackaging. This not only improves operational efficiency but also ensures that each piece of fresh produce undergoes less handling, contributing to a reduction in the likelihood of bruising or damage.

Remove Cardboard from the Supply Chain

Plastic returnable containers offer several advantages over cardboard when it comes to transporting fresh produce, making them a preferred choice for growers in the supply chain.

Plastic containers are inherently more durable than cardboard. They provide robust protection for fresh produce during transportation, reducing the risk of physical damage, crushing, or punctures.

Unlike cardboard, which is typically single-use, plastic returnable containers are designed for multiple trips. This reusable nature reduces the demand for constant production of new packaging materials, contributing to a significant decrease in overall packaging waste.

Plastic is inherently moisture-resistant, providing an additional layer of protection for fresh produce. In contrast, cardboard can become weakened and compromised when exposed to moisture, potentially leading to a breakdown of the packaging and a loss of product integrity.

In conclusion, the use of plastic returnable bins in the fresh produce supply chain goes beyond sustainability, addressing key issues related to freshness, quality preservation, and labor efficiency. As the industry continues to prioritize these factors, these containers emerge as a multifaceted solution that benefits businesses, consumers, and the environment alike.

YOYOBin Adjustable Lightweighting Revolution in the Automotive Supply Chain

In the ever-evolving landscape of the automotive industry, efficiency is the key to success. Manufacturers constantly seek innovative ways to enhance performance, reduce costs, and minimise environmental impact. One groundbreaking solution gaining traction in the automotive supply chain is lightweighting, which is at the forefront of our design thinking for the YOYOBin Adjustable.

Lightweighting is a strategic approach that involves replacing heavy materials with lighter alternatives without compromising structural integrity. In the context of the automotive supply chain, this translates to using lightweight returnable packaging solutions to ship parts. The benefits of lightweighting are far-reaching and extend across various facets of the automotive supply chain, from cost reductions to achieving sustainability goals.

Fuel Efficiency and Emissions Reduction

One of the primary advantages of lightweighting in the automotive sector is the significant improvement in fuel efficiency. Lighter vehicles require less energy to operate, resulting in reduced fuel consumption and lower greenhouse gas emissions.

The YOYOBin Adjustable has a weight capacity of 900kgs and a maximum tare weight of 53kg, depending on size, enabling you to ship large heavy parts using a lightweight packaging solution, that replaces a heavy steel stillage.

Using the YOYOBin Adjustable, you remove significant amounts of weight per truck, compared to using a steel stillage. Therefore saving a considerable amount of fuel and reducing the carbon emissions generated. The YOYOBin Adjustable is a foldable plastic container designed to be safely stacked for return shipping, resulting in up to 260 folded containers per trailer being shipped. In comparison to shipping empty steel stillages which has the same capacity per trailer on outbound journeys as the inbound journey.

Tri-Wall Circular’s commitment to sustainability aligns seamlessly with the industry’s push towards cleaner, more environmentally friendly transportation solutions.

Cost Savings Throughout the Supply Chain

Tri-Wall Circular’s focus on lightweighting extends beyond the end product – it is seen at every stage of the automotive supply chain. Lighter materials reduce shipping costs, as less energy is required to transport components. Additionally, manufacturers benefit from reduced material and end-product cost, leading to more cost-effective and competitive products.

Sustainability and Circular Economy

Tri-Wall Circular embraces the principles of a circular economy by promoting the use of recyclable materials. Lightweighting, when coupled with sustainable materials, aligns with the automotive industry’s growing commitment to reducing its environmental footprint. By adopting materials that are easily recyclable, our containers contribute to a closed-loop system, minimising waste and supporting a sustainable future.

Future-Proofing the Automotive Industry

As the automotive industry undergoes rapid transformation, with an increasing focus on electric and autonomous vehicles, lightweighting becomes even more crucial. Electric vehicles, in particular, benefit significantly from reduced weight as it directly impact the range and efficiency of the vehicle’s battery. Tri-Wall Circular’s YOYOBin Adjustable positions it at the forefront of future-proofing the automotive supply chain, to ship lighter parts in a fully recyclable, foldable plastic container.

Tri-Wall Group Launch Tri-Wall Circular: Sustainable Solutions in the Plastic Returnable Container Market

Tri-Wall Group, a global leader in packaging solutions, proudly announces the launch of Tri-Wall Circular, a strategic initiative aimed at revolutionising the plastic returnable container market.

With a commitment to fostering sustainable and environmentally friendly global supply chains, Tri-Wall Circular introduces innovative solutions in the form of YOYOBin Adjustable and YOYOBin Nestable, designed to meet the evolving needs of customers in the Automotive, Industrial and Fresh Produce sectors.

As Tri-Wall Group continues to experience exponential growth, the expansion into the plastic returnable container market reflects its dedication to supporting clients in building resilient, sustainable and cost-effective supply chains.

YOYOBin Adjustable – first Modular Returnable Packaging Container

The YOYOBin Adjustable provides the global Automotive OEMs and Tier Suppliers with the first modular foldable plastic container, optimised for multi-modal global shipping and 100% recyclable at the end of its lifecycle.

YOYOBin Adjustable has 3 sizes of interchangeable sides, removing the need to purchase multiple returnable packaging solutions.

With a 900kg weight capacity, YOYOBin is designed to replace single-use packaging and steel stillages from the supply chain, supporting OEMs to remove waste and heavy goods from their operations.

YOYOBin Nestable – a fully nestable solution for global shipping

YOYOBin Nestable enhances freshness and quality for fresh produce growers to introduce into their supply chain, from harvest and processing to shipping and cold storage.

A fully nestable footprint enables customers to stack, store and ship the YOYOBin Nestable efficiently, significantly reducing space required, optimising trailers, and reducing carbon emissions generated in the supply chain.

Creating Sustainable Supply Chains

Tri-Wall Circular’s foray into the returnable market is driven by a vision to provide sustainable alternatives that align with global environmental goals and supporting customers to create circular economies within their supply chains.

By introducing groundbreaking returnable packaging solutions, the company aims to address the unique challenges faced by industries striving for a greener and more efficient approach to packaging.

The Tri-Wall Circular team brings an unparalleled wealth of knowledge and experience to the plastic returnable packaging industry. With expertise spanning design, inception, production, and supply chain consultancy, the team is poised to deliver comprehensive solutions that redefine sustainability standards in packaging.

The two revolutionary returnable packaging solutions, tailored for the Automotive and Fresh Produce sectors, showcase Tri-Wall Circular’s dedication to addressing sector-specific challenges. These solutions are designed to enhance efficiency, reduce waste, and promote circular economies within supply chains.

Tri-Wall Group invites its valued partners, stakeholders, and the broader industry to join them in this exciting journey towards a more sustainable future. Tri-Wall Circular represents a significant step forward in the company’s global mission to be the leading packaging supplier, combining innovation, expertise, and environmental responsibility.